There are many types of moisture-proof pads on the market, and it is not time-consuming to understand their characteristics before purchasing.

A. Foam plastic moisture-proof pad:

This kind of moisture-proof pad is the most common variety. It is made of high-pressure polyethylene material, and after foam molding, it is cut into sheets of a certain thickness according to different specifications, which has become our common moisture-proof pad. The characteristics of this moisture-proof pad are closed cells and non-absorbent water. It is usually 45 times foamed and cut to a thickness of 0.8-1.0, and the price is relatively low. Due to its low durability, it is usually disposable in foreign countries. my country is a low-consumption country, and people's consumption habits hope to be used many times to reduce investment. To meet this requirement, some businesses have combined low-expansion and high-expansion slices. This is the double-layer two-color moisture-proof pad we have seen on the market. Because the outer layer uses low-expansion slices, its bottom The wear resistance is greatly enhanced. The advantages of this mat are extremely low price and very light weight (negligible); but the disadvantages are also obvious: poor durability, odor for the first time (mainly toxic gases released by polymer materials), unhealthy for health and long time Although the taste is gone, the toxic substances are still being released slowly.

B. EVA moisture-proof pad:

From its name, we can know the material it uses. EVA is also known as pull-back glue. Compared with closed-cell foam moisture-proof pads, it has good elasticity and toughness. Therefore, the price is also quite different from that of the first type of moisture-proof pads. The cost is nearly doubled, but the comfort and durability are greatly improved. However, from the perspective of its appearance, it is difficult for ordinary consumers to distinguish the difference between the two. Real moisture-proof pads of EVA materials are rare in the domestic market.

C.XPE moisture-proof pad:

XPE moisture-proof pad, also known as semi-porous bubble pad, uses ultra-high pressure polyethylene material. Although this material is not as high-grade as pure EVA materials, its strength, toughness and tensile strength are much better than closed-cell foam materials, but its water repellency is not as good as closed-cell materials. Therefore, when manufacturers make this moisture-proof pad, they pass the process High temperature rigidity for skinning treatment to enhance water resistance. This moisture-proof mat through skinning (embossing) not only enhances the appearance and water repellency, but also improves the toughness, and due to the grooves of the pattern, the breathability is also better. XPE is a new variety launched in the past two years, the price is slightly higher than closed-cell foam materials, and the comfort of use has obvious advantages. It can be said that it is an ideal variety in low-grade moisture-proof pads.

However, from the appearance, XPE is not as dense as foamed plastic, but feels a bit rough, which often leads to misunderstandings, thinking that its comfort is slightly worse, but it is not. The biggest advantage of XPE is that no toxic chemical components are added to its material, and it does not emit a disgusting smell. This is the real reason for its higher price.

In general, the above three moisture-proof pads are all economical and practical products. Some products are covered with a layer of aluminum foil in order to improve the thermal insulation effect, but please note that the cost of covering aluminum foil is not high.

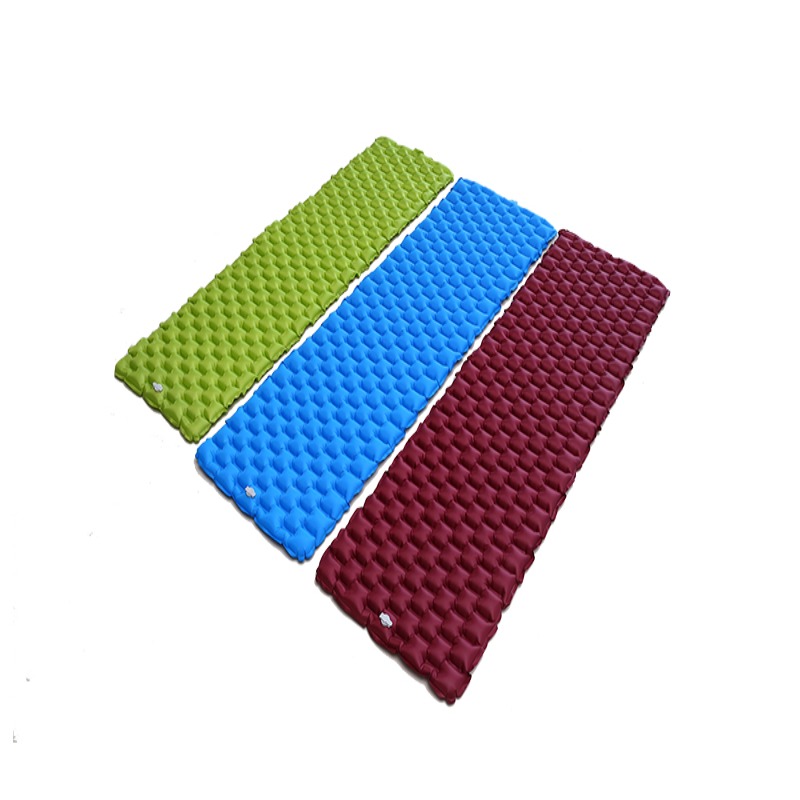

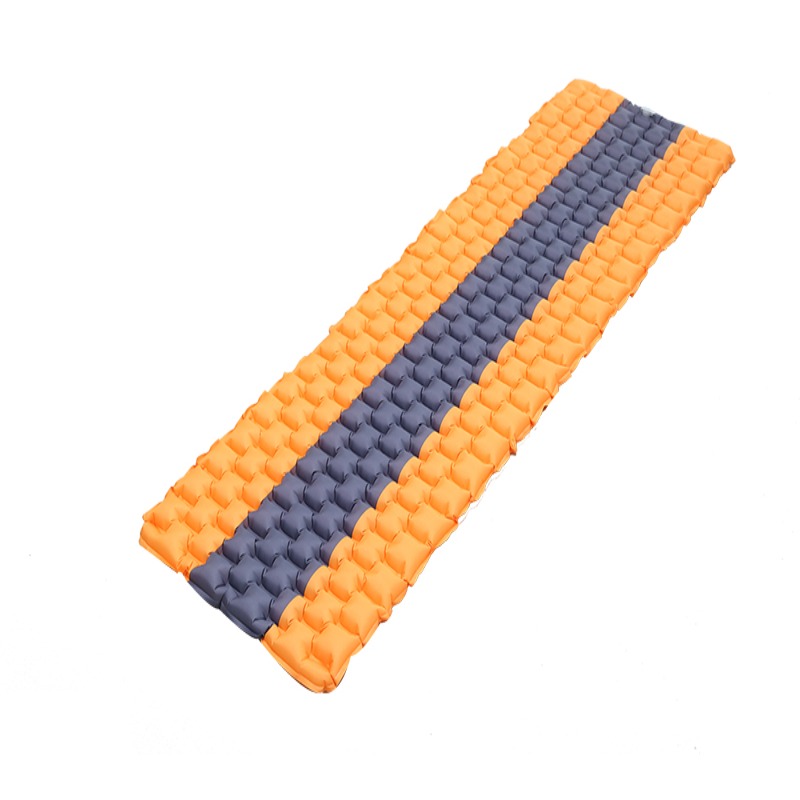

D. Inflatable moisture-proof pad: (air bed)

This kind of moisture-proof pad called an air bed was first used as a floating pad for water in China, and was later used by some people as a moisture-proof pad for camping. This kind of air bed made of cotton scraping rubber fabric has moisture-proof performance. Not bad, but due to its large size, heavy weight (it may reach more than 7 kg), and inconvenient inflation and exhaust, it is an uncommon variety in the family of outdoor moisture-proof pads.

E. Automatic inflatable damp pad:

The self-inflatable moisture-proof pad is a noble of the moisture-proof pad family and is a high-end product. The best mats are sold for more than 2,000 yuan. They are often the first choice for outdoor corrupt travel. They are very comfortable to use and feel like Simmons in the family. In the manufacturing process, the inside of the moisture-proof pad is filled with a sponge with good compression and expansion, squeezing the gas in the sponge, and closing the gas nozzle to make the pad into a semi-vacuum state, and the volume will become smaller. Open the air nozzle, under the action of external air pressure, the sponge expands and can automatically draw air into the pad, so it is called an automatic inflatable pad, and the air-filled moisture-proof pad has very good elasticity.

This type of moisture-proof mat is divided into high, medium and low grades due to different materials. Low-end generally uses polyester-coated polyester silk, so the quality will reach more than 1 kg. In the middle and high grades, PU coated polyester silk is often used, and the inner core is made of high-quality sponge, so the compression and toughness are very good. The bonding method can be divided into three methods: edge sealing, semi-bonding and full bonding. The high-end products are all processed by full bonding. After the air is filled, the mat looks seamless, so the comfort is very good. Because this kind of cushion is filled with a sponge, the general volume is relatively large. In order to reduce the volume of the cushion, some varieties cut the sponge into a honeycomb shape. When strongly compressed, the volume will be greatly reduced, and the weight can also be controlled at 700 However, due to the complexity of the process, the price will be more expensive.

简体中文

简体中文 English

English 日本語

日本語 Español

Español Deutsch

Deutsch